Cawoods' Catch of the Day!

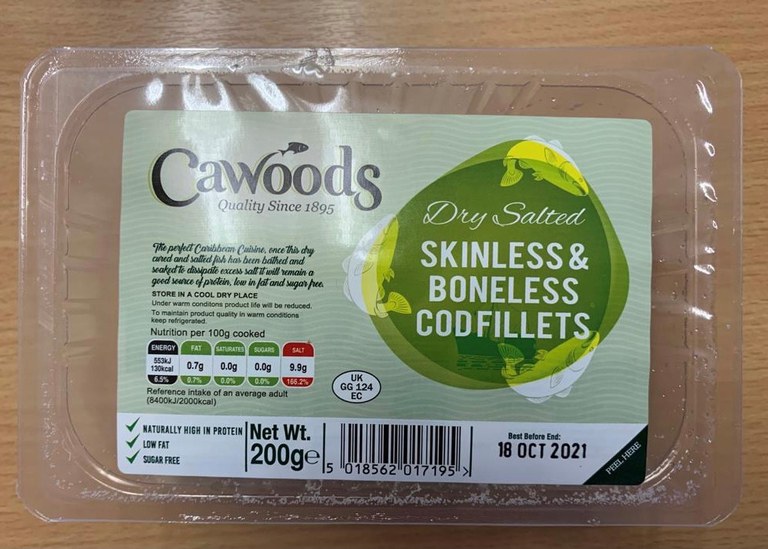

Cawoods Ltd has been a processor of dried salted fish for over 113 years. Over this time, the experienced fish curing business has built one of the most recognised brands of saltfish products in the UK, and prides itself on the traditional methods used.

The technique of preserving fish through drying and salting is a tradition that has endured for centuries. The company attributes this process to producing flavourful fish because of the salt, a satisfying meaty texture due to the drying process, and the benefit of a long product shelf-life. The business also credits the packaging of its saltfish to maintaining the excellent quality of its products.

Once the fish has been air dried and cured, it is essential that it is protected from any moisture, as this would spoil the contents. With Cawoods Ltd producing from its Grimsby factory and supplying the UK as well as exporting to both Portugal and the Caribbean, the robustness of the packaging, specifically to withstand transportation and provide protection from external moisture, is therefore very important.

To help keep up with the demand for its salted fish products and maintain excellent packaging protection, Cawoods Ltd turned to ULMA Packaging UK (ULMA), who helped the fish curing business replace its 15-year old ULMA machine with a brand new one.

A new catch of the day

Matthew Hudson, Accountant at Cawoods Ltd, said: “We have been reliant on a now 15-year old ULMA packaging machine that has served us well over the years, but it was time for an upgrade. It made sense to go back to ULMA as the previous machine had worked so well for us. We needed a company who understood our business and the harshness of the packaging conditions, due to all of the salt used, and we knew that they could deliver a solution keeping this in mind.”

Why the TFS 300?

Thanks to ULMA’s reputation as a provider of a world-renowned range of thermoforming packaging machinery, Matthew at Cawoods Ltd was keen to find out all the possible options and solutions. Following a consultation, Cawoods Ltd chose the TFS 300 hygienic design thermoformer.

Andy Hayward, Regional Sales Manager at ULMA, commented: “The TFS 300 thermoformer was chosen as it is ideally suited to Cawood’s packaging needs. It is built to provide a hygienic film barrier over the product, which is extremely important to keep the salted fish protected. With the harsh salt environment, it was also important that any machine chosen could withstand such scenarios. The touch screen UPC control system also provides a clear and easy to use display, adding to the functionality of the model.

“A major plus of the TFS 300 is that it is so easy to clean and there are no edges that can retain product remnants either. The internal elements are also designed to support a high degree of resistance to water and dust with an IP rating of 67 and 69. These attributes make the equipment ideal for deep cleaning using high water pressure and meet the criteria and recommendations of the worldwide food safety standards.”

Packaging improvements

Since the TFS 300 has been introduced, Cawoods Ltd has experienced an increase in production from 21 packs per minute to 36.

ULMA was also chosen by Cawoods Ltd based on the reliability of its service personnel, who had previously maintained the company’s previous ULMA machine. As a result of this strong relationship, Cawoods Ltd had further incentive to choose ULMA and did not hesitate to agree a full-service package to help keep the new TFS 300 running smoothly.

Matthew at Cawoods Ltd, explained: “We are very pleased with the service that ULMA can provide, not only when initially recommending a machine and improving our production speeds, but the aftercare support that’s on offer too. It’s not an option for our machines to take unscheduled downtime, so knowing we have the ULMA team on-hand should we need them to fix or service our new TFS 300 is great.”