HOT TOPIC: Environmental sustainability

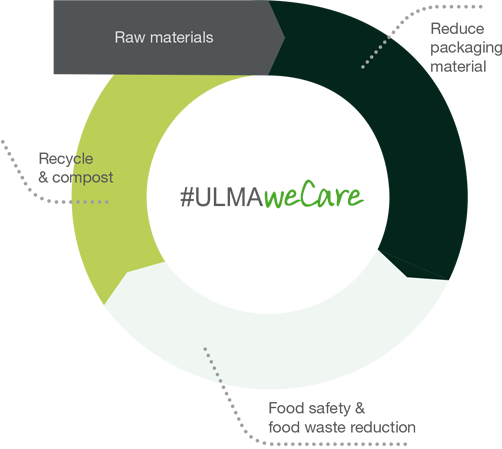

Food manufacturers and producers, from bakeries to vegetable farmers, are under increasing pressure from consumers and retailers to tackle plastic use and waste. To help support the food industry, ULMA has invested in researching and developing a new range of packaging solutions and machines as part of the #ULMAwecare project.

Launched this year at the IFFA trade show in Frankfurt, the #ULMAwecare project demonstrates ULMA’s commitment to working with industry partners to reduce packaging and promote the use of recyclable materials throughout the process.

As a result, ULMA has sought to advance sustainability through innovation with the introduction of a range of environmentally-friendly packaging solutions, such as:

- LeafSkin - a packaging solution that can reduce plastic use by up to 80% and is based on a 100% recyclable flat cardboard tray.

- Flow-Vac - a lower reel machine, with the roll stock fed from below the level of the product feeding line. This optimises the required use of plastic.

- ReducedScrap - a Cryovac Darfresh packaging solution with a film scrap reduction of up to 40%.

- Tight-Bag - an innovative packaging solution that optimises the volume of the bag by removing excess air from the packaging.

What every sustainable packaging solution requires is a machine capable of delivering those extra sustainability credentials such as:

- Thermoformer TFS 200 MSV - an all-in-one solution capable of delivering MAP, SKIN and VACUUM packages on one machine and providing manufacturers with a reduction in plastic film use.

- Thermoformer TFS 407 R for ReducedScrap - a Darfresh thermoforming machine that uses up to 40% less scrap than other machines while delivering up to a 12% cycle speed increase.

- Traysealer TSB 300 - capable of delivering four packaging options on one machine (MAP, basic SKIN, SKIN protruding and airpack) and can use a 100% compostable tray.

- Flowpack wrapper FM 505 - able to deliver high-speed MAP packing and is ready to use thin gauge films for reduced packaging.

With consumers demanding food products with less and less plastic, manufacturers in the food industry must keep pace. Sustainable innovation can change the way in which food manufacturers and packers deliver their products to consumers. Lowering plastic use while maintaining the quality of the product that customers have come to expect.