ULMA Expands Medical and Pharmaceutical Packaging Solutions

With the United Nations reporting 210 million face mask units distributed worldwide last year, ULMA has created bespoke solutions to meet the specifications of any type of mask, regardless of shape, size, or the type of fastening used.

The solutions have been developed with the highest sector standards in-mind to guarantee the reliability and safety of the final product. As a result, ULMA’s machine capabilities are suitable for packaging both surgical and FFP2 masks.

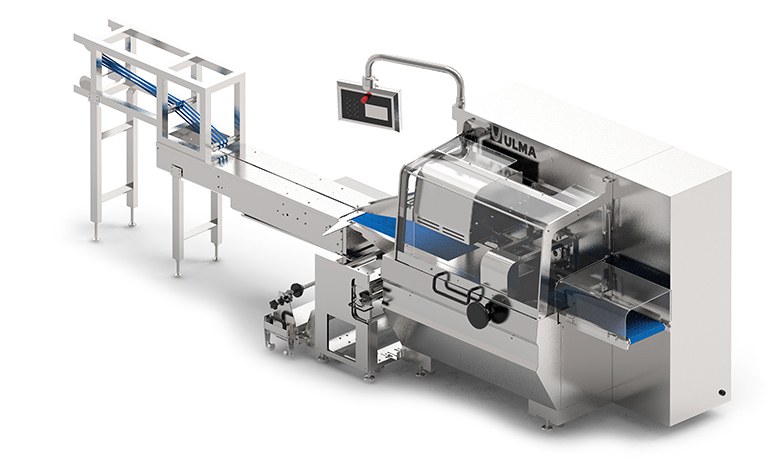

ULMA’s expanded range of machines can be used to package in individual formats and in groups. This includes flow wrapper packaging machinery technology with automatic face mask feeding systems. Additionally, a diverse array of materials can be used, such as plastic, aluminised film, medical paper and Tyvek to protect the products from microorganisms and humidity.

It is also possible to incorporate technological systems for labelling and coding that guarantee traceability for all the data that must be included on the product, such as the batch number, serial number or barcodes.

Machines and automation projects for all types of mask

ULMA's packaging machines make it possible to combine different materials and customise the final package to adapt it to the characteristics and specifications of any type of mask, regardless of its shape and size, or the type of fastening it uses.

We also have a wide range of technology solutions, which allows us to design automation projects. In this case, masks are taken off the production line and then grouped and fed into the packaging machine, either individually or as a group.

Flow Pack wrapper with automatic face mask feeding system

Our machines can be used to package in individual format and in groups, and they are able to package the safest masks against Covid-19: surgical and FFP2 masks. Epidemiologists calculate that they offer between 94% and 95% protection against the virus, which has led countries such as France and Germany to prohibit the use of fabric or home-made masks and make this type of mask mandatory in certain public areas, a decision that has had an immediate impact on sales figures.

Specialists in medical and pharmaceutical products

At ULMA, we are specialists in packaging sterilised products and medical devices and we offer all kinds of Medical and Pharmaceutical solutions that meet the strictest sector standards. Comprehensive and fully automated solutions, ULMA includes everything from the handling and loading of the product, to it being packed in boxes and on pallets. Our solutions are compatible with plastic materials, aluminised film, medical paper and Tyvek to protect the products from microorganisms and humidity. ULMA's wide range of solutions ( Flow Pack (HFFS), Flexible and Rigid Thermoforming, Vertical (VFFS), Traysealing and Shrink Wrapping) means we can offer our customers the packaging technology that best suits their product.

The resulting packages can include easy-open systems such as pre-cuts and grip holes to improve functionality, and they adapt to the shape and characteristics of each product. The option of using different materials in the same machine or even the same package makes our solutions incredibly versatile. It is also possible to incorporate technological systems for labelling and coding that guarantee traceability for all the data that must be included on the product, such as the batch number, serial number or barcodes.

Our Medical and Pharmaceutical catalogue contains packaging solutions for single-use disposable plastic devices; medical textiles, gauzes and sponges; injectable products; medical devices designed for surgery and examinations, such as drills, scalpels and prostheses; and products designed for sale in pharmacies that require economical packaging in cartons or boxes, or that need some type of mechanical protection for over-the-counter sale.

Ed Williams, Sales Director at ULMA Packaging UK, commented: “At ULMA, we are specialists in packaging sterilised products and medical devices. This not only includes high-grade face masks, which has been a key packaging focus for the business as we’ve expanded our offering, but across all kinds of medical and pharmaceutical solutions. From flow pack, flexible and rigid thermoforming, vertical, traysealing and shrink wrapping options, ULMA can apply the latest in packaging innovation and technology to best meet the needs of medical and pharmaceutical products.”

Please contact us for your medical packaging needs.